There's an ineffable majesty to a well-maintained running track - the sleek, pristine surface, the meticulously marked lanes, the promise of adrenaline-pumping races and personal bests. But have you ever wondered what a running track is made of? The answer offers a unique exploration into the background and evolution of athletic engineering and design.

Overview

The material used to make running tracks can vary greatly, depending on the level of competition, budget, location, and desired durability. However, most modern running tracks, especially those used in competitive athletics, are made from synthetic materials that offer runners optimal speed, traction, and shock absorption. The story of how we arrived at today’s more commonly used poured-in-place polyurethane tracks represents a 70-year journey dating back to the mid-1950s and the introduction of the first synthetic all-weather surface.

Olympic Influences

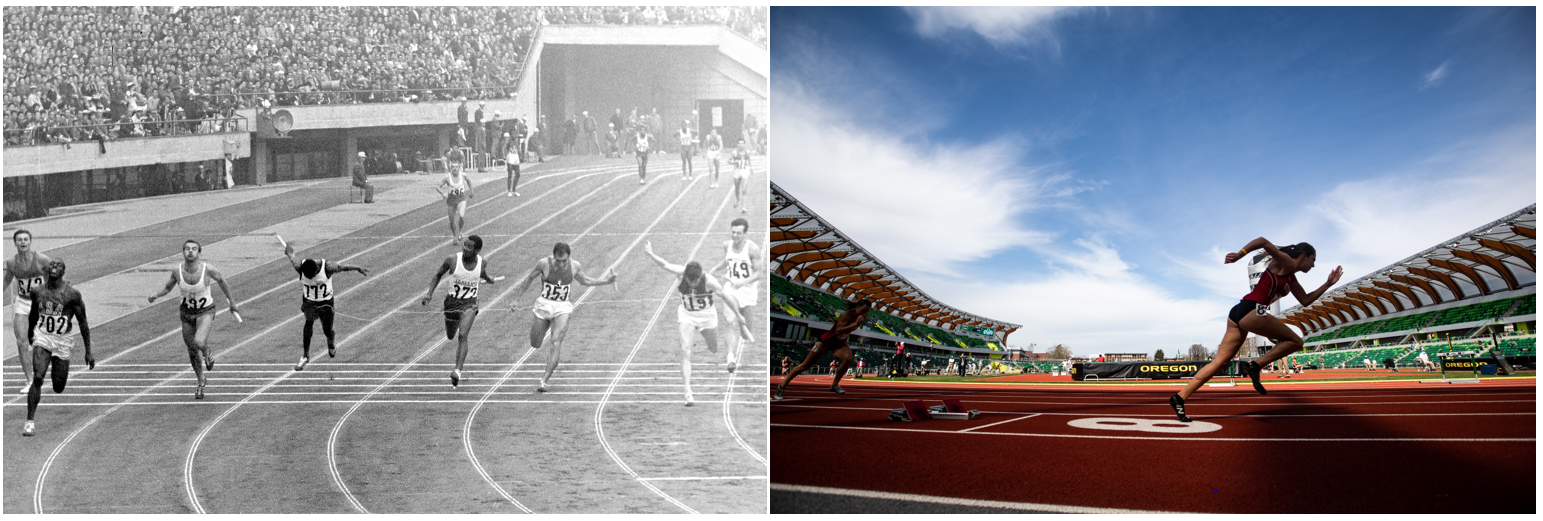

The first all-weather tracks were designed primarily to replace those traditionally made of cinder. The surfaces, a combination of rubber and asphalt, gained sufficient popularity to be used in an artificial warm-up track built for the 1956 Summer Olympics in Melbourne.

The natural evolution of track technology resulted in the advent and popularization of polyurethane surfaces in the 1960s, helping to leave the days of cinder tracks firmly in the past. The 1964 Tokyo Olympics were the last to use cinder, with the transition to synthetic surfaces solidified by their adoption at the 1968 Games in Mexico City.

Not only were the new tracks lauded by athletes for enduring various conditions without significant wear and tear, but they also spurred advancements in footwear, including the introduction of shorter spikes. With new tracks using asphalt or concrete as a durable base and synthetic surfacing to provide greater flexibility and cushioning, longer spikes were no longer essential for piercing cinder surfaces.

Polyurethane Dominance

Following the 1968 Olympics, praise surrounding synthetic tracks gained further momentum, with continued success at subsequent Summer Games in Munich and Montreal. Polyurethane, now the standard for world-class athletic competitions, has continued to evolve in its ability to deliver superior performance characteristics, including a balance of traction, comfort, and energy return, resulting in faster times while increasing athlete safety.

In 1974, John Beynon founded the company that would become Beynon Sports, and by the 1980s, its ability to craft high-performance polyurethane sports surfaces was gaining national recognition. To achieve consistently high performance, a polyurethane track is comprised of multiple layers. The bottom layer is usually a mix of black rubber granules and a binding polyurethane. The top layer, known as the wear layer, contains a mixture of colored rubber granules and a more weather-resistant polyurethane. This layer can be pigmented to achieve the classic red color we associate with running tracks or any other color according to a facility’s specifications.

The Road to Becoming the Most Trusted Surface in Track & Field

With its emerging reputation, Beynon Sports was selected to build running tracks for the 1990 and 1998 Goodwill Games, the 1992 Olympic Trials in New Orleans, and countless NCAA and Conference Championships. Today, Beynon is the market leader, with its Baltimore-based plant specializing in designing, manufacturing, and installing polyurethane athletic surfaces for outdoor running tracks at colleges and universities nationwide. Beynon is also the leader in hydraulic, banked, and flat indoor tracks, employs over 375 people, and has more than 7,500 installations on its roster, including five World Athletics Class I Certified Facilities in the United States, the most among all manufacturers.

In 2022, the Beynon track at the University of Oregon’s Hayward Field was at the surface of the first World Athletics (WA) Championships in the U.S. and will be at the surface of the 2023 Wanda Diamond League Final in September 2023. It will be the first time that the final takes place outside of Europe since the event began in 2010.

Conclusion

The science of running track design relies on expertise across numerous disciplines, including materials engineering, sports construction, athlete safety, and even environmental impact. These are areas where the Beynon Sports team is unrivaled in its ability to deliver first-class solutions.

Every Beynon track is constructed at their advanced manufacturing facility at the Hunt Valley, Maryland company headquarters. The facility is one of the few in the industry to have its Quality Management Systems certified to ISO 9001.

Whether an athlete seeking faster times, a facilities manager considering future upgrades, or simply a passionate fan of track and field, understanding the history of its evolution and the technical components that support elite performance is essential to deepening one’s appreciation of the sport.